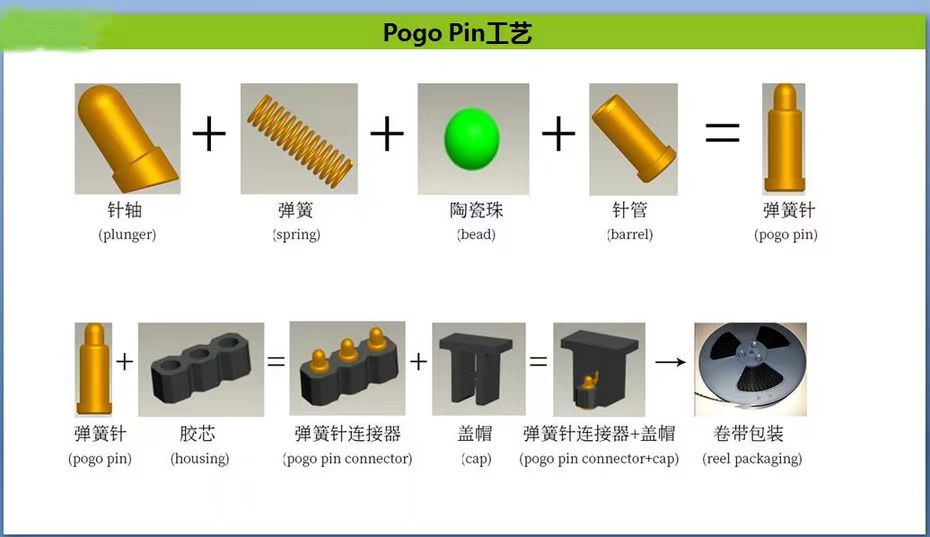

Pogo pin production process from raw material processing to finished product assembly has the following processes:

1. Turning: Select a copper bar and add it to the feed tube of the feed machine, and fix it. The machined parts should be measured according to the drawings to confirm whether the parts meet the requirements of size and tolerance, and whether the appearance requirements are observed through a microscope.

2. Needle tube alignment: pour a proper amount of needles into the alignment frame, set the machine parameters, then put the alignment frame into the alignment machine and press the green start button to fix the alignment frame. The machine vibrates to make the needles fall into the holes.

3. Spring arrangement: pour a proper amount of springs into the spring arrangement plate, then hold the spring plate and the arrangement frame firmly and shake them back and forth to make the springs fall into the holes.

4. Needle alignment: Pour a proper amount of needles into the alignment plate, and then shake the needle plate and the alignment frame back and forth to make the needles fall into the holes.

5. Riveting: Check whether there is a lack of spring or needle shaft. The products with skewed needle are straightened with tweezers. After confirmation, lightly place the finished plate on the platform of the riveting machine according to the direction, and the riveting machine will automatically rivet.

6. Full inspection of compression: compress each needle for 3-5 times with the indenter, and check whether there are any undesirable phenomena such as crooked needle, needle shrinkage, needle folding, crush injury, electroplating color difference, coating falling off, etc.

7. Rubber core, single needle alignment and rotating plate: pour a proper amount of single needle into the alignment plate, and then shake the single needle plate and the alignment frame back and forth to make the single needle fall into the hole.